Product Description

|

CHINAMFG |

|||

|

Country of CHINAMFG |

HangZhou,China |

||

|

Type |

Engine Parts |

||

|

OEM |

VG1560080300 | ||

|

Normal or Customized |

|||

|

Package |

Plastic bag |

Front oil seal | 1 |

| VG260571208 | Flywheel gear ring | 1 | |

| AZ1242571561 | Flywheel assembly | 1 | |

| VG1246030011/12 | Connecting rod tile | 1 | |

| VG1246571034/35 | Main bearing | 1 | |

| AZ1246030007 | Connecting rod assembly | 6 | |

| VG1246030013 | Connecting rod bolt | 12 | |

| VG1246030015 | Piston assembly | 6 | |

| VG1540030005 | Piston ring | 1 | |

| VG1246030002 | Piston pin | 6 | |

| VG1246571571 | Cylinder liner | 6 | |

| D12.42-XLB | Engine repair kit | 1 | |

| VG1246040571 | Cylinder pad | 6 | |

| VG1246050571/22 | Intake and exhaust valve | 1 | |

| VG1246 0571 1 | Valve push rod | 12 | |

| VG1246 0571 1 | Valve tappet | 12 | |

| VG1246060091 | Belt | 1 | |

| VG1246060005 | Automatic tensioning wheel | 1 | |

| VG1246060094 | Pump assembly | 1 | |

| VG1246060088 | Belt | 1 | |

| VG1246060051 | Fan leaves | 1 | |

| VG1246070012 | Oil cooler core | 1 | |

| VG1246080002 | High-pressure pipeline | 1 | |

| VG1246090017 | generator | 1 | |

| VG1246090002 | starter | 1 | |

| VG124611571 | Turbocharger | 1 | |

| VG1246130008 | Air compressor | 1 | |

| VG12465716 | Fuel injector assembly | 6 | |

| WG9731471571 | Steering vane pump | 1 | |

| VG1246070031 | Oil filter | 2 | |

| VG1540080110 | Diesel filter | 1 | |

| VG | Diesel filter | 1 | |

| WG9725195712/103 | air filter | 1 |

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

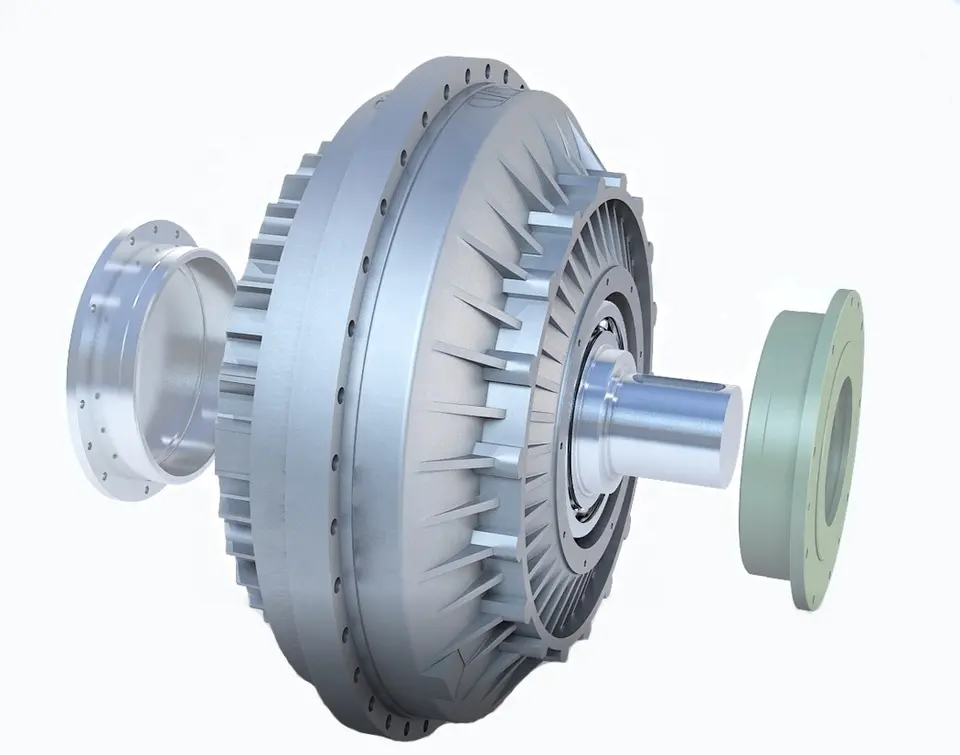

Protection Against Leaks and Contamination in Oil Couplings

Oil couplings are designed with various features and practices to prevent leaks and contamination, ensuring their reliable operation:

- Sealing Mechanisms: High-quality seals and gaskets are used at critical points to prevent oil leakage and entry of contaminants.

- Seal Maintenance: Regular inspection and replacement of seals and gaskets help maintain their integrity and prevent leaks.

- Enclosures: Some oil couplings are housed within protective enclosures that shield them from external debris, dust, and moisture.

- Oil Filtration: Some systems incorporate oil filtration units to remove contaminants and particles from the oil before it enters the coupling.

- Oil Analysis: Regular oil analysis helps monitor the condition of the lubricant and detect contaminants or degradation early.

- Proper Installation: Precise installation and alignment reduce the risk of seal damage and misalignment-related leaks.

- Clean Environment: Maintaining a clean operating environment minimizes the likelihood of contaminants entering the coupling.

- Oil Reservoir Design: Well-designed reservoirs and chambers within the coupling can prevent oil from escaping and contaminants from entering.

- Seal Design: Advanced seal designs with protective features can provide enhanced resistance to leaks and contamination.

Through these protective measures, oil couplings can effectively safeguard against leaks and contamination, ensuring their continued performance and reliability.

Handling High Torque and Variable Speeds with Oil Couplings

Oil couplings are well-suited for applications that involve high torque and variable speeds due to their unique design and operating principle. Here’s how they handle these challenges:

- High Torque: Oil couplings can effectively handle high torque levels by using the fluid’s viscosity and shear properties to transmit torque. As torque increases, the viscosity of the oil also increases, enhancing its ability to transmit power. This characteristic allows oil couplings to withstand sudden spikes in torque without causing damage.

- Variable Speeds: Oil couplings are inherently capable of accommodating variable speeds. The viscosity of the oil can adjust to changing speeds, ensuring smooth power transmission even when the rotational speed varies. This flexibility is particularly beneficial in applications where the load or operating conditions may change frequently.

By relying on the fluid properties of the oil, oil couplings can maintain stable and efficient power transmission across a range of torque levels and speeds. This makes them suitable for applications that require high torque, variable speeds, and adaptability to changing operating conditions.

Challenges from Improper Oil Coupling Maintenance and Avoidance

Improper maintenance of oil couplings can lead to various challenges that affect performance, efficiency, and the overall lifespan of the machinery. Here’s how to avoid these challenges:

Oil Contamination: If contaminants like dirt, water, or foreign particles enter the oil, it can compromise the lubrication and cause excessive wear. Regularly inspect and change the oil according to manufacturer recommendations to prevent contamination.

Insufficient Lubrication: Inadequate oil levels or improper oil viscosity can lead to insufficient lubrication. Monitor oil levels and choose the right oil viscosity as per manufacturer guidelines to ensure proper lubrication.

Overheating: Operating an oil coupling at high temperatures without proper cooling mechanisms can cause the oil to break down, leading to reduced lubrication properties and potential damage. Implement cooling systems if necessary and monitor operating temperatures closely.

Oil Degradation: Over time, oil can degrade due to oxidation, thermal stress, and chemical reactions. Regularly check oil condition and replace it if signs of degradation are detected. Scheduled oil analysis can help predict oil degradation and replacement times.

Incorrect Oil Selection: Using the wrong type of oil with improper viscosity and properties can affect coupling performance. Always refer to manufacturer guidelines and recommendations for selecting the right oil for your specific coupling.

Infrequent Inspections: Lack of regular inspections can result in undetected issues, leading to potential failures. Implement a regular inspection schedule to identify any signs of wear, leaks, or other problems early on.

Ignoring Manufacturer Recommendations: Manufacturers often provide maintenance guidelines for their specific oil couplings. Ignoring these recommendations can lead to suboptimal performance and premature wear. Always follow the manufacturer’s maintenance instructions and recommended intervals.

Improper Installation: Incorrect installation can lead to misalignment, poor engagement, and premature wear. Follow proper installation procedures and ensure accurate alignment to prevent these issues.

Lack of Training: Inadequate operator training can result in improper oil coupling maintenance. Provide proper training to operators and maintenance personnel to ensure they understand the coupling’s requirements and maintenance procedures.

By addressing these challenges through regular maintenance, following manufacturer guidelines, and implementing best practices, you can ensure the optimal performance and longevity of your oil couplings and the machinery they are a part of.

editor by CX 2024-03-02

by

Leave a Reply